The day's first deployment went smoothly.

The day's first deployment went smoothly.

The goals for our second day out were to find out what altitude is best for taking pictures, and to see if Justin's changes to the survey behavior could help straighten out the tracklines when the vehicle is at depth. In this test, we stepped through altitudes from 1.8 meters to 1.1 meters in increments of 10 centimeters. The results are exactly what we had hoped for: consistently good images, and a better idea of what range of altitudes will produce them.

In this test, we stepped through altitudes from 1.8 meters to 1.1 meters in increments of 10 centimeters. The results are exactly what we had hoped for: consistently good images, and a better idea of what range of altitudes will produce them.

Notice the difference in the amount of red channel as the vehicle approaches the bottom. To get good information from red light, we have to fly very close to the bottom. A difference of a few tens of centimeters makes a big difference in light quality!

We also had one flash misfire, the cause of which is unknown.

Overall, this set of images is a huge success; we can start doing image surveys in earnest now that we know the physical focus and aperture settings are in the right place. The new survey behavior also worked well... mostly. The tracklines are much straighter, but what happened at the 4th corner?

The new survey behavior also worked well... mostly. The tracklines are much straighter, but what happened at the 4th corner?

Before we could wonder too much, Justin noticed that the vehicle was running in circles under remote control and had a problem with rolling over.

Uh oh. Mike and Seth sprang into action to check it out.

Mike and Seth sprang into action to check it out. Both thruster cables were still attached. So, we decided that recovering Odyssey would be the only way to fully determine the cause of the problem. Kyle got to try his hand at recovery.

Both thruster cables were still attached. So, we decided that recovering Odyssey would be the only way to fully determine the cause of the problem. Kyle got to try his hand at recovery.

Only 3/4" of the thruster was still within the coupling. Had it worked its way fully loose, we would have lost it permanently!

Unfortunately, there was a second problem as well: the RTU had fallen out of alignment, and was unable to produce adequate torque on the shaft to properly position the thrusters. This is a game ender; we have to take the RTU back to the lab for disassembly.

On the steam back to the harbor, I was able to put together a small mosaic of a few good images using the hugin panorama stitcher (not to be confused with the Hugin AUV).

On the steam back to the harbor, I was able to put together a small mosaic of a few good images using the hugin panorama stitcher (not to be confused with the Hugin AUV).

When the RTU is fixed, we should be in very good shape to get more like this!

The Search for Didemnum: Day 2 (Double Success, Double Failure)

Tuesday, October 6, 2009

Battery Scare in the 11th Hour!

Friday, October 2, 2009

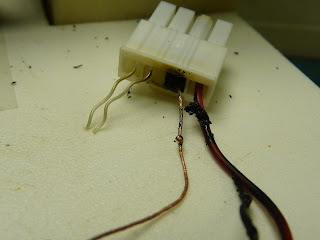

Some part of the battery had short circuited; something was seriously wrong!

We had to take the battery apart again to see what happened and to try and fix it. We are especially under the gun to fix this, because we are supposed to deploy on Monday to look for didemnum! Yikes!

We count ourselves very lucky that only one supercell was damaged and that nothing caught on fire. In the end, we had to use the supercell that had been removed as the replacement for the one that was damaged (although we recharged it). A net gain in the end, but only a small gain.

Posted by Ian at 2:59 PM

Labels: battery, failure, short circuit

Nantucket Sound Testing, Day 2

Tuesday, August 18, 2009

Mike operates the crane, Mike and Seth fend the vehicle off of the gunwales, and Noah guides both the crane and the quick release. We're still getting the hang of this part.

Then something familiar happens...

Then something familiar happens...

The vehicle starts going in circles when it should be going straight. Have we lost a thruster again? Seaweed? Mike and Seth check it out in the zodiac... apparently the cable got wrapped around the thruster and had disconnected.  So, Seth grabbed a handful of zip ties and went to secure the cable.

So, Seth grabbed a handful of zip ties and went to secure the cable.

Posted by Ian at 8:16 PM

Labels: failure, field operations, fishing

Disaster Strikes!

Tuesday, July 14, 2009

Our 3-D printed mechanical fuse for the RTU coupling cracked and broke, taking our thruster to the bottom of Gloucester harbor.

Justin: Mike, the vehicle is going in circles instead of forward. Can you check the connection to the thruster?

Mike: Sure.

(Pause)

Mike: What thruster?

It would have ordinarily been retained by the electrical cable but ... we had just set it up to unplug rather than put strain on the other cable. "Whoops" doesn't quite capture the disappointment.

Posted by Ian at 8:10 PM

Labels: disaster, failure, more deployments than recoveries

There's Your Problem...

Thursday, July 9, 2009

Since this was largely the result of wires and plugs being crowded near the top of the bottle, I drilled a hole in the mounting plate for the PC boards and routed some of the wires to the back side.

Dead Battery

Monday, May 4, 2009

After 3 years of faithful service, our battery was accidentally allowed drain far below the acceptable minimum voltage for Li-ion cells, effectively ruining its capacity. In fact, it would be unsafe to recharge this battery in its present under-voltage state.

We will have to build a new battery. This is unfortunate, but since these cells lose 20% of their capacity per year in perfect storage conditions, it was inevitable.

This will push our schedule back a bit...